New Zealand engineers are among the world’s leaders when it comes to earthquake engineering—everyone in Christchurch right now might like to pause at some stage and say a silent “Thank you” to the men and women who designed the structural systems that kept them safe through an earthquake of the same strength that killed hundreds of thousands of poor souls in Haiti last January.

So I thought over the next few days, by way of thank you, I’d start showing you just a few of the ingenious creations of seismic engineers that help keep people safe, beginning by re-posting a system I talked about a few months ago, the “K-braced frame.”

There are people who say engineers aren’t creative. Not true. Just look at this cunning rearrangement of traditional structural elements that makes tall buildings less expensive to build for earthquakes, safer in an earthquake, and more likely to be useable afterwards.

And it’s a pretty good theme. You see, the main aim in earthquake design is to make sure people can get out safely – which means to avoid the building collapsing. The K-brace (and its cousins the V-brace and the D-brace) do that and much more: they also make it easy to repair the building after an earthquake so that it can get straight back into action – which is pretty important for a major hospital.

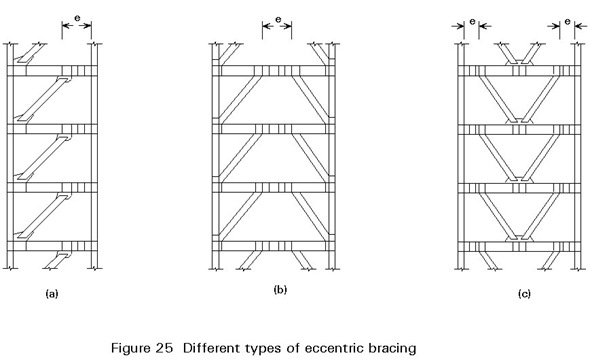

The two key elements of these bracing beauties are, 1) the “triangulation” of the structural members, and 2) that little piece labelled ‘e’ on the drawings above. ‘e’ is actually called a “link”—a “sacrificial link.”

The seismic engineer uses the nature of both geometry and earthquakes to make your tall building safer. And how he does it is so elegantly simple it’s almost laughable. He does it by making that little link act like the fuse in your fusebox.

So as the building moves from side to side in a quake (and some quakes can go for a minute or more, meaning lots of shimmying) that link is working up and down and up and down so many times it eventually turns the heavy section steel into chewing gum. Into plastic. And and in the process of being deformed, it’s absorbing much of the earthquake’s energy that would otherwise have gone into destroying the parts of the building that hold it up.

But as long as our sacrificial link is turning to plastic, then our beams and columns aren’t. That’s the beauty of the system. Let the link die, and use it to absorb and save the building and its occupants—and afterwards, by way of repair, all that’s often needed is to take out the deformed links and replace them with new ones.

Now how’s that for ingenious. Taking the same materials normally used in a building frame, and placing them in an arrangement designed to better combat earthquakes. And since creativity consists of “the power to rearrange the combinations of natural elements” then this sort of ingenuity is the very acme of creativity, and much more interesting than most of the stuff that flies under that flag.

2 comments:

What is the difference between these and X bracing though? I would suspect X bracing adds additional support to structures in the event of an earthquake. Which one would be better for a 1 to about 5 story wooden building in the event of an earthquake? Thank you.

So what the K-bracing adds is that sacrificial link, which has the added bonus of adding (or allowing) xtra ductility to both brace and structure.

Post a Comment