“Ductile, a., malleable, not brittle; capable of being moulded; pliant, tractable, yielding to persuasion or advice…”

Most buildings don’t use the sort of fancy nancy systems I’ve already described like base isolation or K-braced frames. They use something more subtle and much less expensive called “ductile design”—not making buildings strong so much as making them flexible.

You might think that answer for better earthquake protection is to make buildings stronger and more rigid. But this is no more true for a building in an earthquake than it is for a car in a crash. The best kind of car to drive into a brick wall is not one that’s strong and rigid, but one that crumples in a way that protects the occupants and absorbs the energy of the crash. And so it is with a building: no building could fight the power of the earth by staying perfectly rigid—such strength acts like a lightning rod to the earth’s forces, inviting your building to be shaken to pieces The best structures in which to ride out an earthquake are designed not to stand up rigidly but to absorb the earthquake’s energy by yielding gently while the earth moves—in the same way a willow tree moves with the wind instead of standing up to it rigidly.

People speak of tall buildings swaying during a high wind. Let me assure you, tall buildings sway just as much (or more) during an earthquake, and they’re designed to. Leastways, modern buildings are. And as they sway, the frame of the building is absorbing the violence of that horizontal motion imposed by either wind or earthquake, and transmitting it evenly throughout the joints of the building.

It’s those joints between columns and beams where the ductility of a building’s structure is really designed in. Imagine a chest of drawers with all the drawers out and the back taken off. That’s something like the typical structural frame of your tall building—except in a tall building the joints where uprights meet horizontals are designed to take the strain. Push your chest of drawers from the side and at the top while keeping its feet on the ground, and you’ll hear its joints creaking as they (hopefully) take the strain of your shove. In a building frame that’s been designed with ductility, those joints won’t creak (not if designers and builders have been doing their job) but will instead remain elastic as the building sways gently from side to side.

(Now you understand that a modern building is designed to move during an earthquake, you’ll be less frightened when you feel it moving.)

Naturally, the material of which your building frame is designed makes a difference to how it performs. Ductile is better than brittle.

Steel is a naturally ductile material—at least until successive shakes turn it plastic—so is a popular material in an earthquake zone. Concrete reinforced with steel can be made ductile with careful detailing, especially at those joints. Timber itself is more brittle than ductile, but the things that hold it together (like nails, nails plates, steel connectors etc.) give a timber frame its ductility.

Brick walls, however are not ductile (as you can see in the video below). Not ductile at all. They can be tied back to things that are, but since the brick walls and steel frames to which they’re tied move at different rates, this is not as easy as it sounds. This explains why the Christchurch earthquake was felt so severely by the plaster facades of Christchurch’s heritage buildings, and the brick walls on which those facades were installed.

There are obviously some subtleties involved there that it took some time for even experienced earthquake engineers to discover and work out.

They discovered it was more economical not to design a typical workaday building to be completely damage-free after a quake, but primarily to ensure that people inside will be safe when the ground is moving, and when the shaking does finally stop that they can get out safely—and the building itself can be easily repaired. That If the structural frame is allowed to sway, then you need to detail walls and windows to fit inside these swaying frames so that the movement of the structure doesn’t damage these secondary elements.

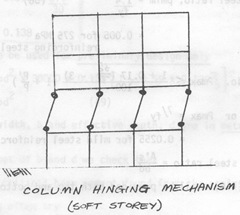

And they discovered that if a ductile building is to remain standing then its beams need to be made to fail before its columns—and that the “plastic hinges” formed as the beams do fail actually help to absorb the earthquake’s energy, protecting the rest of the building. (It was this insight that inspired the plastic “hinges” of the K-braced frames.)

Good:

Ductile design. One of engineering’s primary means of ensuring our buildings can protect us while resisting the worst the earth can throw at them.

UPDATE: Watch this great video:

In seismic design, designing a system to be stronger than the earthquake was typically the approach: “the stronger we make it, the safer we are.” That approach has been proved to be wrong…

Dr Stefano Pampanin from the University of Canterbury explains how the ‘smarter’ idea of ductile design originated at the University in the 1960s and is currently under further developments and refinements. Making buildings stronger is not the answer for earthquake protection.

No comments:

Post a Comment