There are people who say engineers aren’t creative. Not true. Just look at this cunning rearrangement of structural elements that makes tall buildings less expensive to build for earthquakes, safer in an earthquake, and more likely to be useable afterwards.

And it’s a pretty good theme. You see, the main aim in earthquake design is to make sure people can get out safely – which means to avoid the building collapsing. The K-brace (and its cousins the V-brace and the D-brace) do that and much more: they also make it easy to repair the building after an earthquake so that it can get straight back into action – which is pretty important for a major hospital.

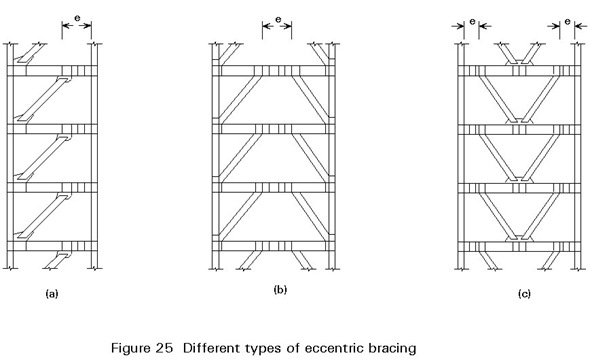

The two key elements of these bracing beauties are the “triangulation,” and that little piece labelled ‘e’ on the drawings above. ‘e’ is actually called a “link.” A “sacrificial link.”

The seismic engineer uses the nature of both geometry and earthquakes to make your tall building safer. And how he does it is so elegantly simple it’s almost laughable. He does it by making that link act like the fuse in your fusebox.

So as the building moves from side to side in a quake (and some quakes can go for a minute or more, meaning lots of shimmying) that link is working up and down and up and down so many times it eventually turns the heavy section steel into chewing gum. Into plastic.

But as long as our sacrificial link is turning to plastic, then our beams and columns aren’t. That’s the beauty of the system. Let the link die, and save the building and its occupants.

And there are two added treats:

- the energy needed to turn the link into plastic helps absorb and dissipate the energy of the quake; and

- when the earthquake’s over, the most major repair you might need to make to your building is to cut out the link and put a new one in.

Now how’s that for elegant. And creative -- indeed if creativity consists of “the power to rearrange the combinations of natural elements,” then this is the very acme of creativity, and much more interesting than most of the stuff that flies under that flag.

7 comments:

Good article - as one of the Project Managers on this job its good to see it talked on positively. Beca were the structural designers and they did a very good job

I would like to see comments from your colleagues, where are they?

This is why timber framed buildings are so earthquake resistant. They can be rolled down a hill and not break a pane of glass.

All the nails are "energy absorbers" and absorb kinetic energy like the "links".

If you could get to the nails after a quake you would they would be hot.

PC

An elegant solution well explained.

Now for the non-engineers you'll have to explain the difference between elastic and plastic deformation!

LGM

Owen

Yup, they would be. And they would likely be elasticlly deformed.

LGM

I am reminded of the cricket commentator who was asked to explain what was meant by "up in the blockhole" and he replied "it means the ball lands right in the blockhole".

So I could say that elastic deformation is elastic and plastic deformation is plastic and funnily enough it might then be clear to many more people.

Elastic deformation is below the limit at which the deformed material fails to return to its original shape or length. A rubber band is elastic and so is a steel rod.

But there is a range at which the elastic material stretches but does not break but does not return. Plasticene is permanently plastic. Risen dough is not properly proofed if it elastic (a thumb press bounces back) but is properly proofed when it is plastic ie the thumb press does not bounce back.

During the plastic deformation the material still absorbs energy. That is why kneading dough is quite hard work.

Owen

Yes. I know what you mean.

---

Plastic deformation is useful in this instance as you can absorb a lot of energy converting it to heat. An elastic deformation on the other hand means that the stored energy is going to be released again mechanically- like a spring. That might not be handy. Ouch!

LGM

Post a Comment